Mesin Granulating PET Efisien Dhuwur

Karakteristik

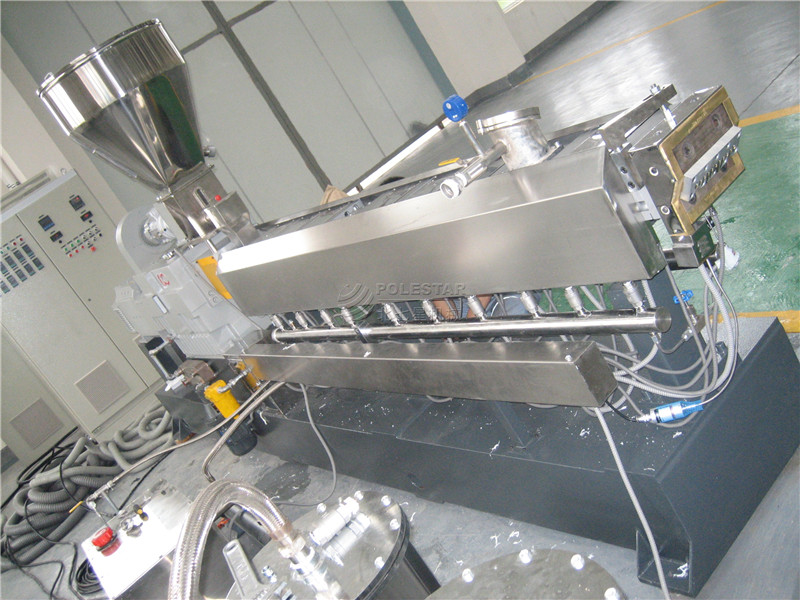

Pelletizer PET utamane kalebu peralatan ing ngisor iki: extruder, pangisi layar hidraulik, cetakan nglereni untaian, conveyor pendingin, pengering, pemotong, sistem blowing penggemar (sistem pakan lan pangatusan), lsp. , output dhuwur karo konsumsi daya luwih murah.

Aplikasi

Mesin pelletizing pet digunakake kanggo nggawe flakes plastik PET menyang pelet utawa granule.Twin meneng extruder daur ulang & sistem pelletizing sing Applied kanggo bahan sampah, kang perlu kinerja Processing dhuwur saka leleh, volatilization, nyaring etc.

Alur Proses

Screw feeder (OPTIONAL)→ Force feeder→ Parallel twin screw extruder → Hydraulic filter exchanger→ Mould head → water cooling tank → Plastik pemotong standar → Kemasan produk rampung.

Katrangan rinci saben Item

1. Screw Feeder: ngirim kethokan Plastik menyang mesin utama.

2. Force feeder: feed materi kanggo extruder karo kacepetan dirancang, kacepetan bisa diatur.

3. Extruder meneng kembar podo: materi plasticizing lan gas kesel.

4. Dhuwur-kacepetan Net exchanging sistem lan Die-kepala: Filter impurity materi, kanggo nggawe produksi luwih stabil.

5. tank banyu: cooling mie PET.

6. Cutter standar plastik: Cut mie PET menyang granuels.

Kaluwihan Kompetitif

1. Kontrol PLC otomatis

2. Kanthi kontrol suhu individu

3. Operasi trep & kinerja Stabil

4. Highly efisien, pangayoman lingkungan lan energi nyimpen

Data Teknis

| Extruder | TSK35 | TSK50 | TSK60 | TSK65 | TSK75 | TSK95 |

| L/D (mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Kacepetan Maks (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Daya Motor (kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Daya Pemanas (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Output Maks (kg/jam) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Kategori produk

Pengin Nambah Langit menyang Desain Sampeyan?

Hubungi kita dina iki kanggo konsultasi desain.